All five of our packaging machinery can cater to a wide range of food industries. Used for packaging food products is the family of horizontal flow wrapping machine such as candy, chocolate, cookies, granola bars, fruits, produce, and more.

As most of you know, if not all, our products only consists of five flow wrapping machines namely;

SleekWrapper 40

SleekWrapper 45

SleekWrapper 65

SleekWrapper Inverted

Breezy Bagger

Packaging Machinery

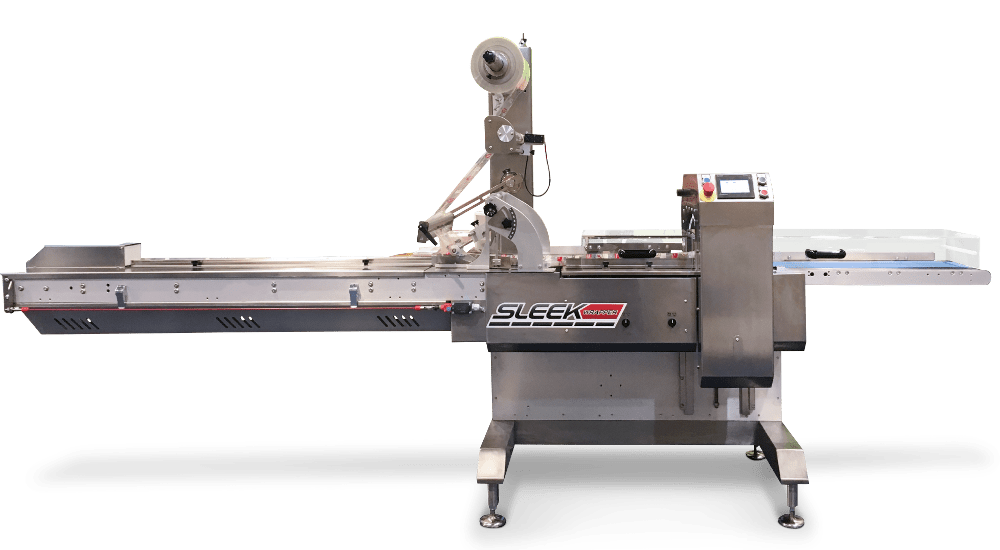

The SleekWrapper 40 horizontal wrapping machine can produce up to 100 packages in just a minute with a maximum web width of 15.5″ and package size of 7” wide and 24” long. Its standard features include a stainless steel frame, driven by 4 servo motors, belt driven, infeed conveyor with snap-in pushers. Cantilevered single film holder, color touchscreen, rotary seal jaws, and more.

Second is the SleekWrapper 45 with its ability to produce up to 150 packages per minute with a maximum web width of 18” and package size of 7.85” wide and 24” long. Some of its standard features include a stainless steel frame, driven by 4 servo motors. Belt driven, 6 feet infeed conveyor, cantilevered self-cantering film holder, color touchscreen , HMI Integrated temperature control, and many more.

Next is the heavy-duty SleekWrapper 65 made with a stainless steel frame and is fully driven by 5 servo motors. It is designed to produce up to 200 packages per minute with a maximum web width of 25.6″ and package size of 11 8” wide and 24” long. Its standard features include belt driven, 6 feet infeed conveyor, cantilevered self-cantering film holder, color touchscreen, HMI integrated temperature control, and many more.

We also have the SleekWrapper Inverted, a servo-driven horizontal flow wrapper. Constructed with a stainless steel frame. It can create up to 100 packages per minute. Along with, a maximum web width of 19.6” and package size of 11.8” wide and 24” long. Standard features include pre-programmable controls for up to 120 recipes, right-hand configuration, belted or lugged infeed conveyor with snap-in pushers, color touchscreen, and so much more.

Breezy Bagger

Lastly, is the dual functioning Breezy Bagger with its skill of wrapping packages horizontally and vertically. It can produce a bag of up to 10” wide and up to 36” long.And package various products in many sizes and shapes. Its standard features are Omron PLC, foot pedal, auto-air regulator, and filter. In addition to lubricator, memory-based storage, and a painted steel frame.