SleekWrapper F45

High Speed

Fastest in the SleekWrapper Line

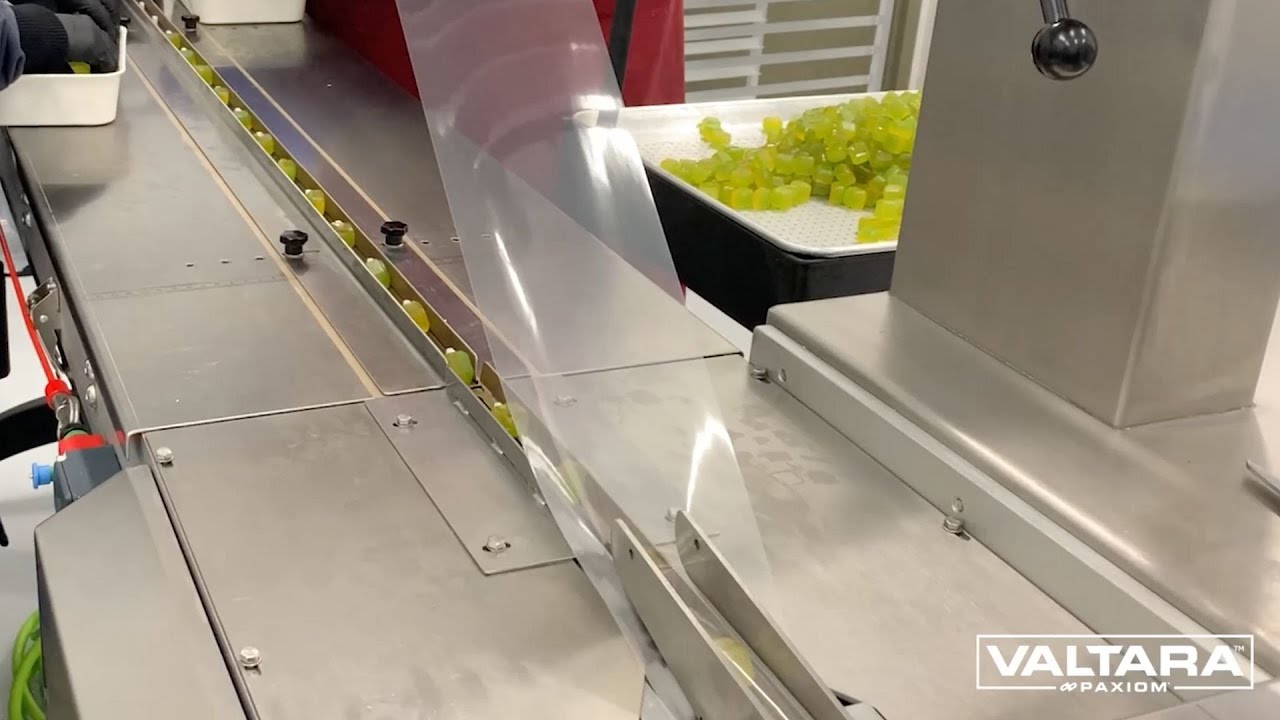

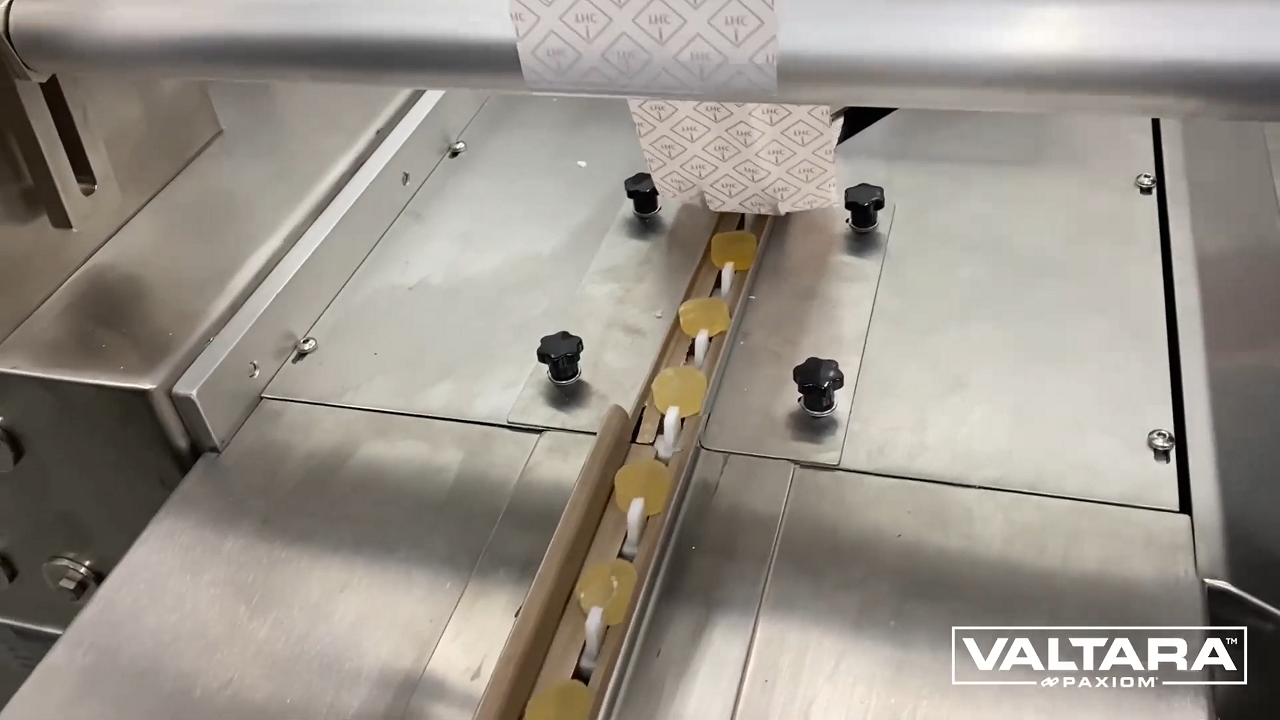

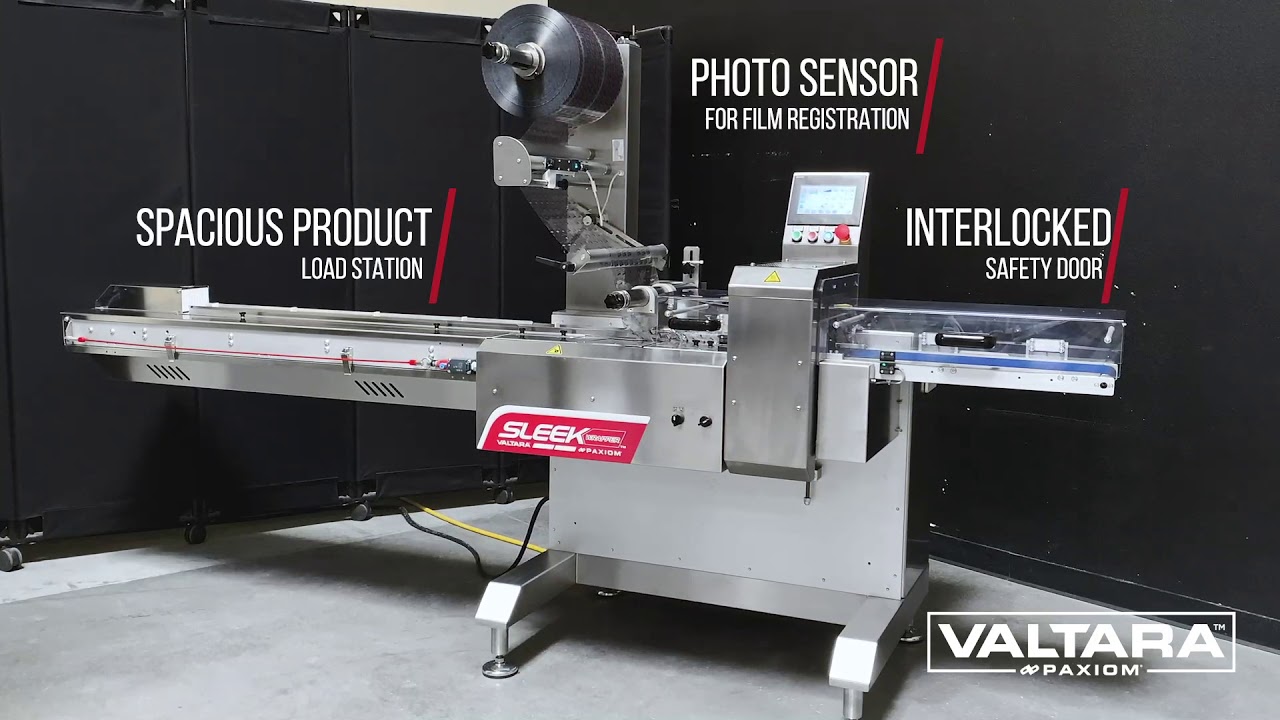

The Sleek F45 flow wrapping machine is designed for high-speed production rates. This reliable machine can be quickly adjusted and products can be changed out easily to minimize product and film waste and reduce maintenance costs. Multiple servo-driven motors assure precise positioning with smooth acceleration and deceleration.

Features stainless steel frame construction, user-friendly color touchscreen, automatic open/close rotary fin wheel assembly, rotary seal jaws with jam detecting logic with the ability to preprogram and store product settings.

| Max Bag Length | Max Bag Width | Max Bag Height |

|---|---|---|

| 17.8 in (450 mm) | 7.85 in (200 mm) | 4.7 in (120mm) |

| Film Web Width | Max Rate | |

| 18 in (450 mm) | 1-up jaw: 80 per min 2-up jaw: 160 per min |

*Rates subject to package style, type and size

SleekWrapper F45

High Speed

The Sleek F45 flow wrapping machine is designed for high-speed production rates. This reliable machine can be quickly adjusted and products can be changed out easily to minimize product and film waste and reduce maintenance costs. Multiple servo-driven motors assure precise positioning with smooth acceleration and deceleration.

Features stainless steel frame construction, user-friendly color touchscreen, automatic open/close rotary fin wheel assembly, rotary seal jaws with jam detecting logic with the ability to preprogram and store product settings.

| Max Bag Length | Max Bag Width | Max Bag Height |

|---|---|---|

| 17.8 in (450 mm) | 7.85 in (200 mm) | 4.7 in (120mm) |

| Film Web Width | Max Rate | |

| 18 in (450 mm) | 1-up jaw: 80 per min 2-up jaw: 160 per min |

*Rates subject to package style, type and size