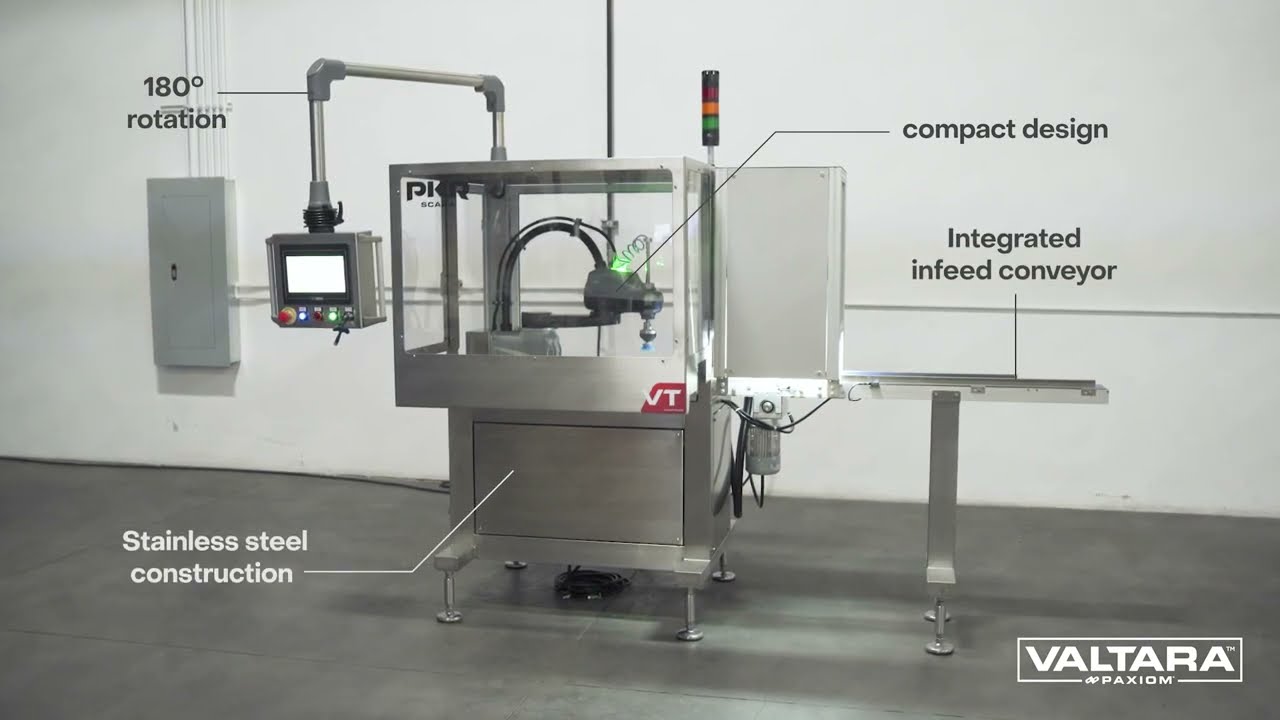

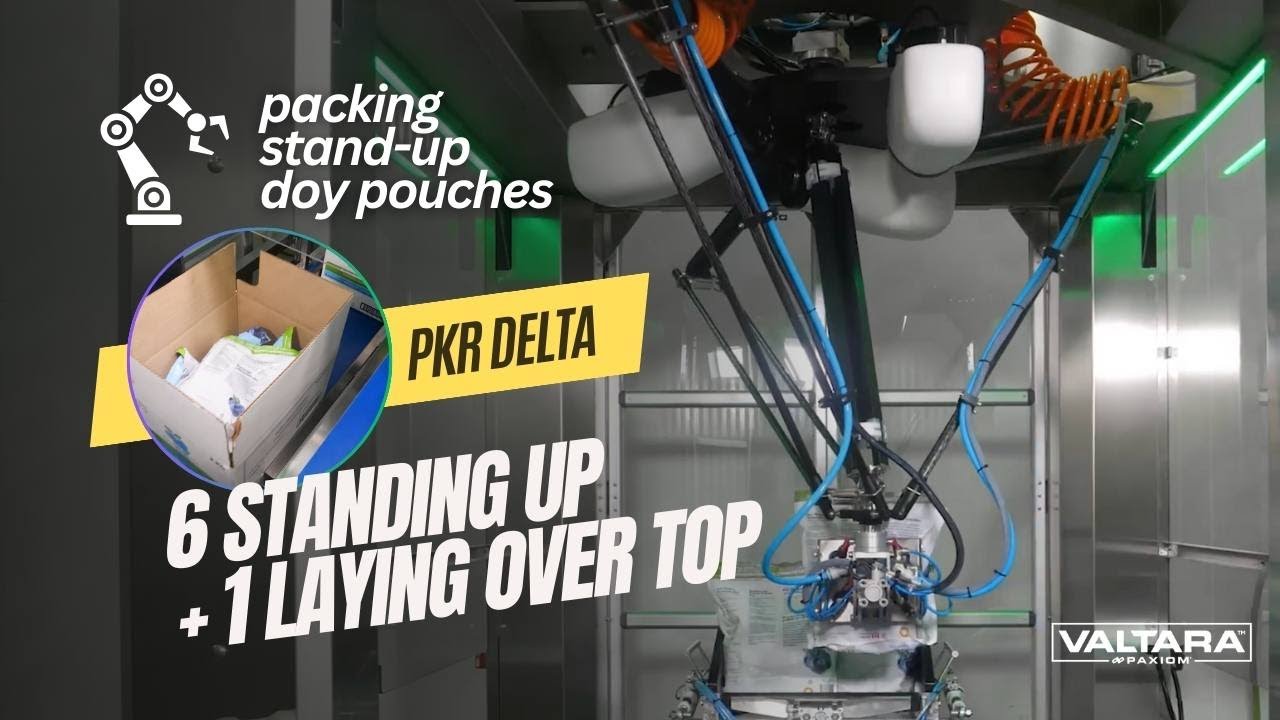

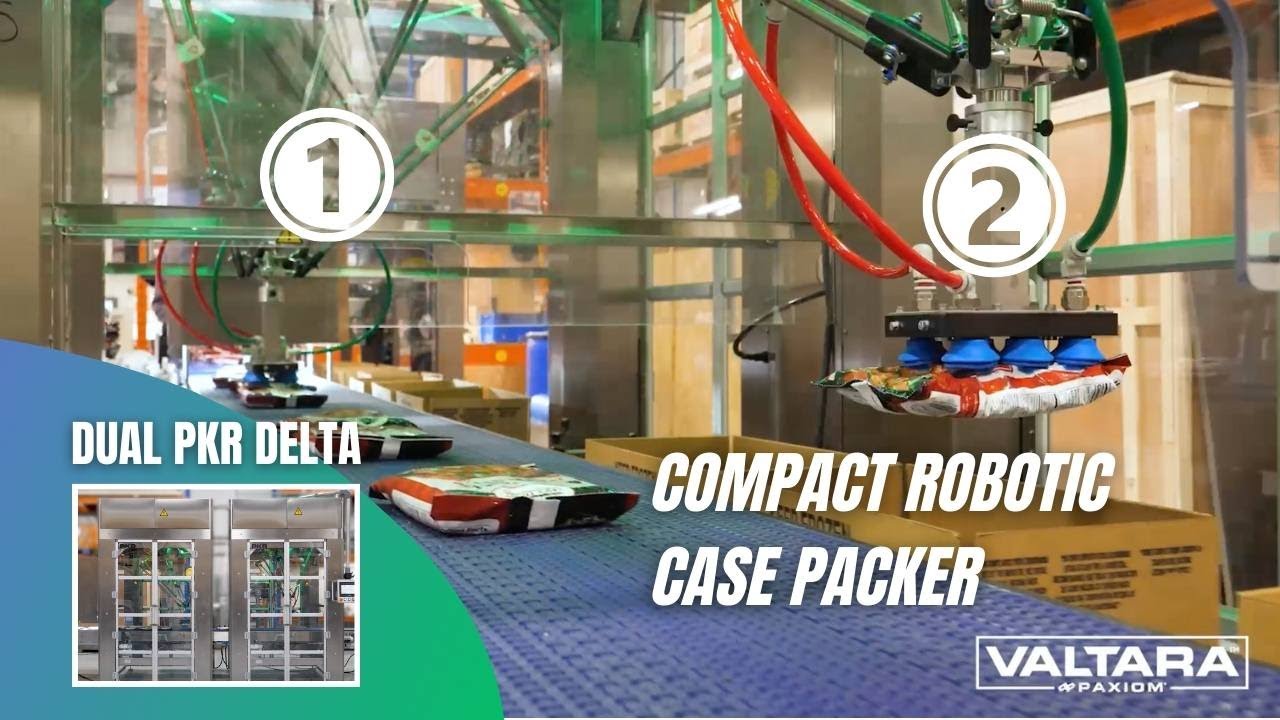

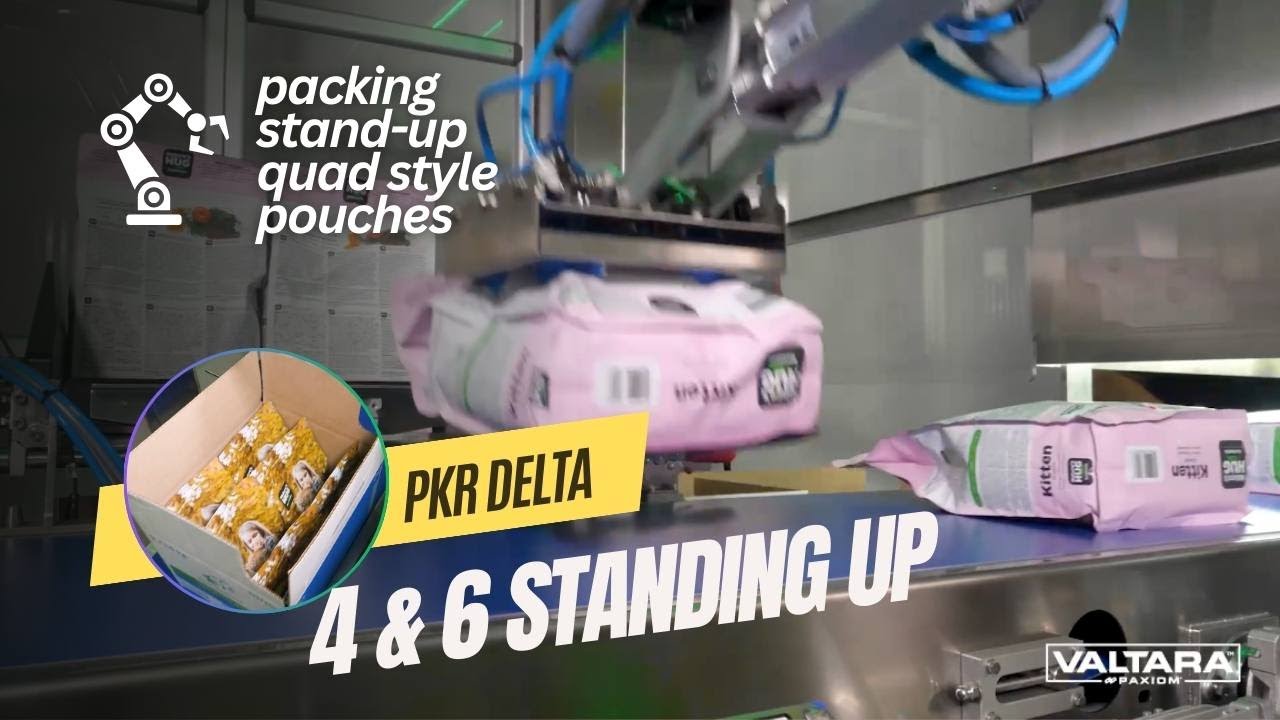

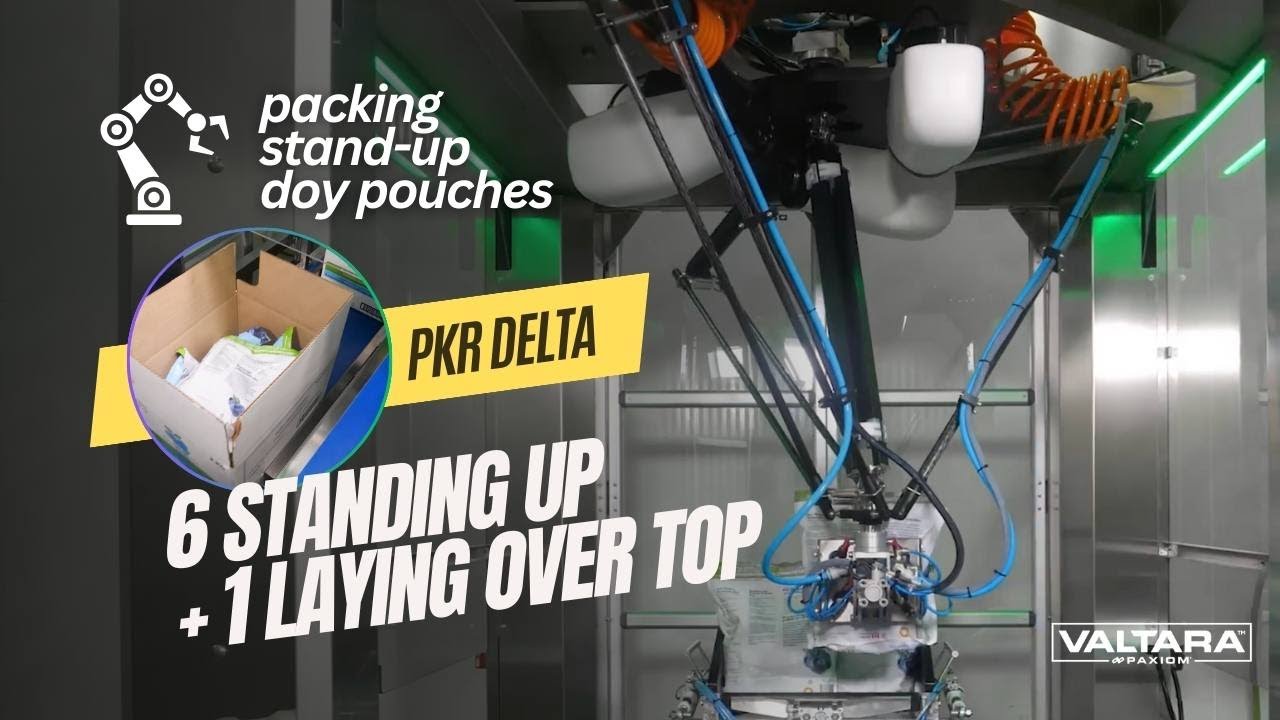

PKR Delta

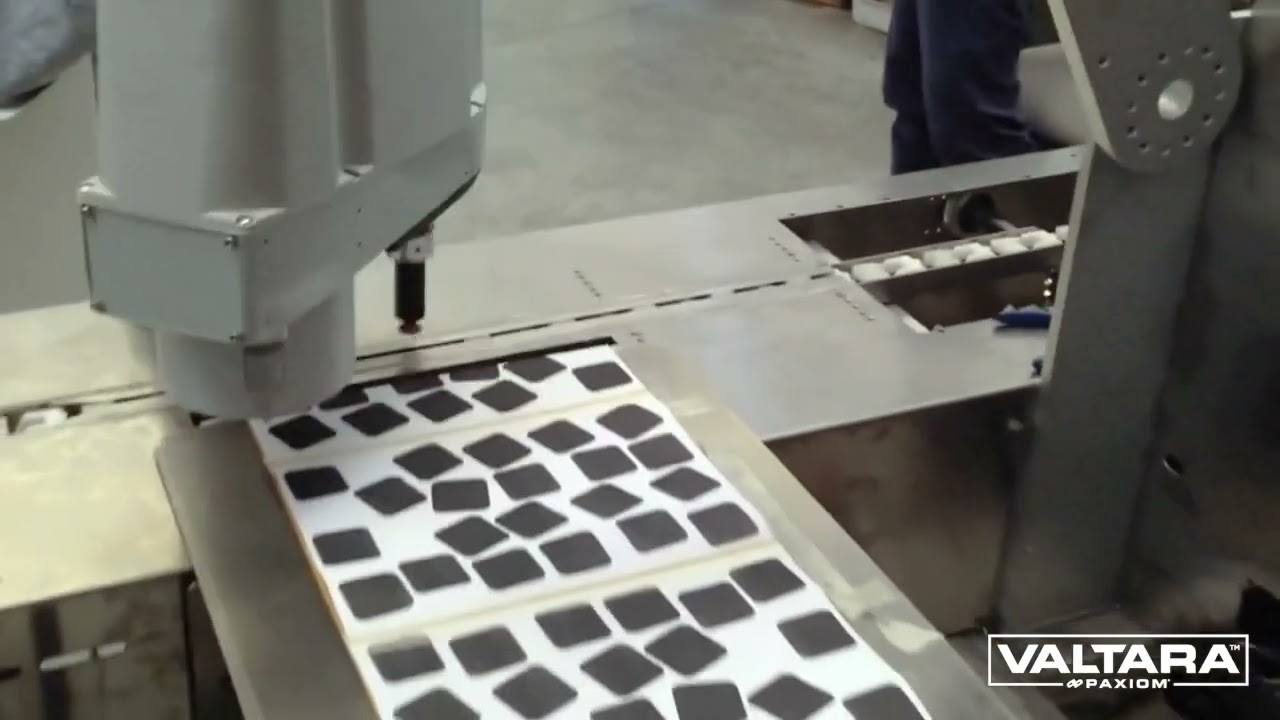

Delta Spider Pick & Place Cell

Videos

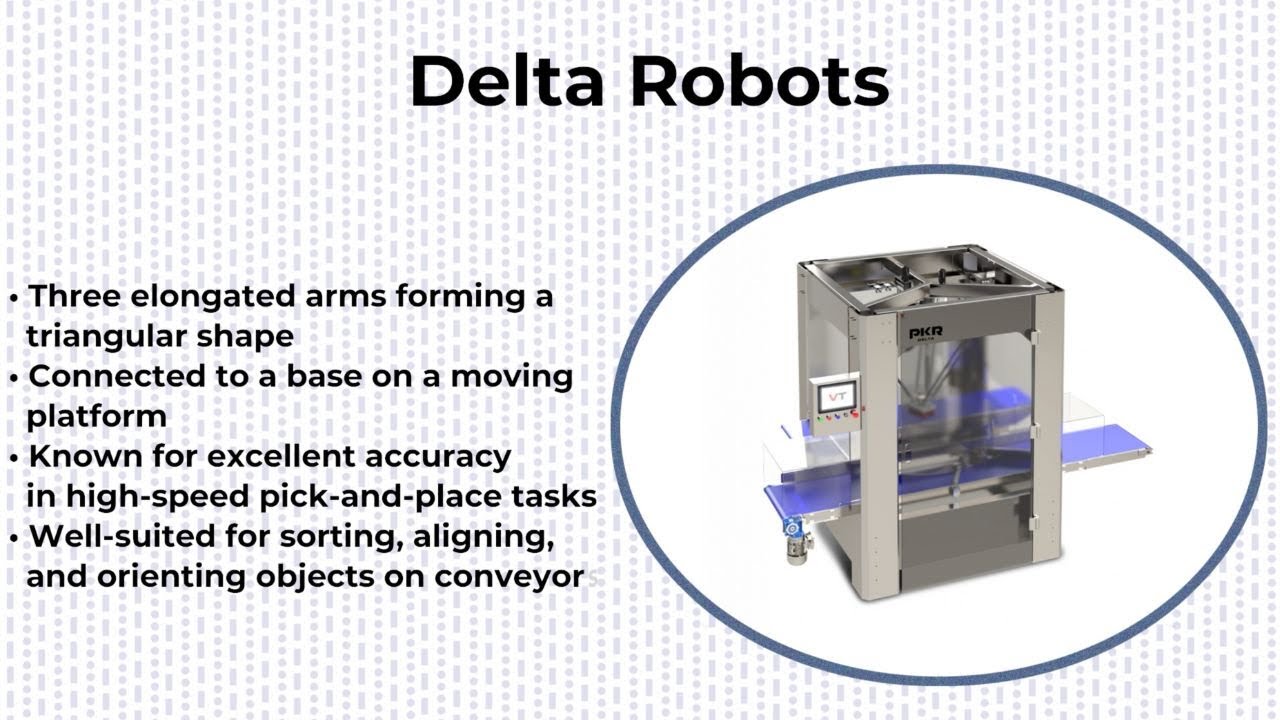

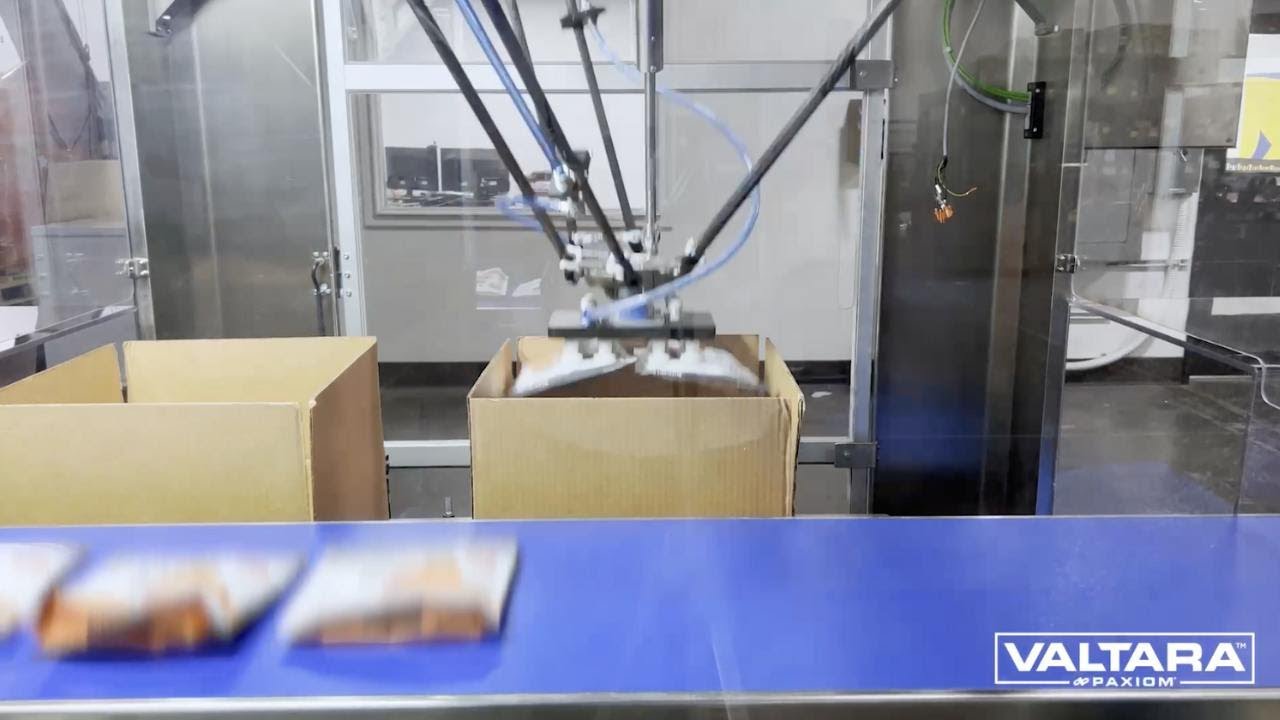

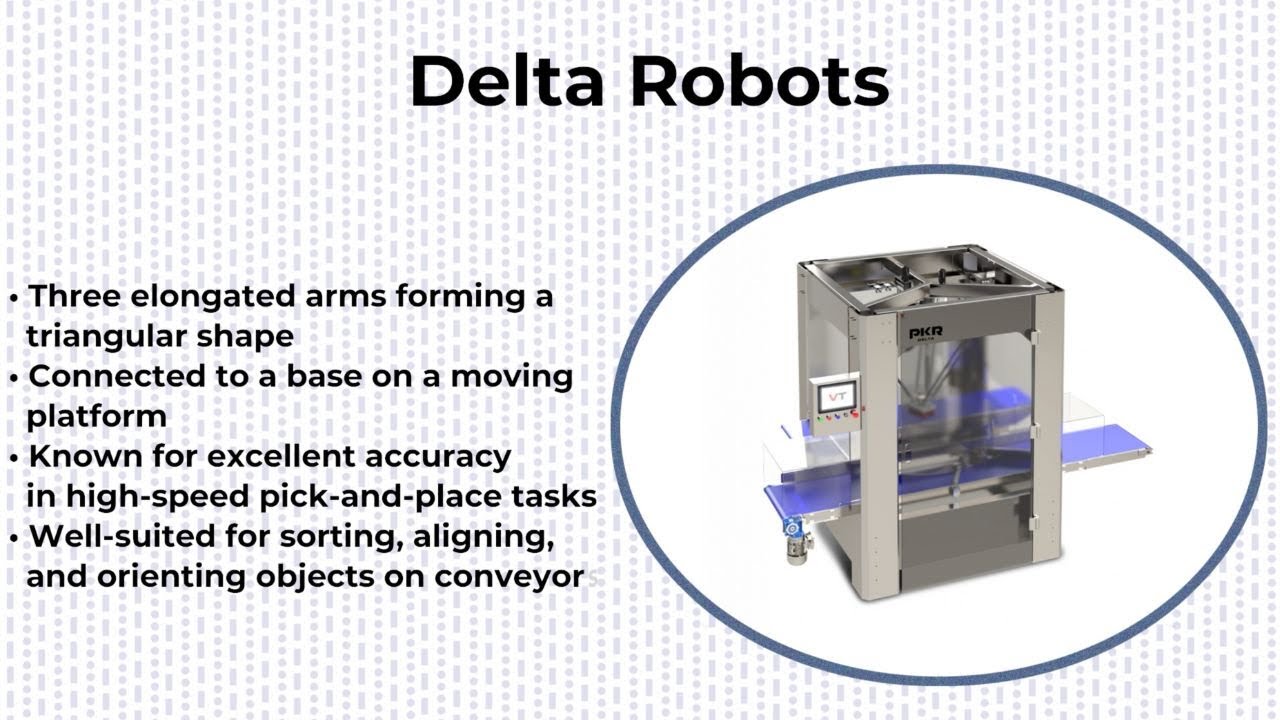

Our PKR modular pick & place cells will automatically top-load your product into cases or trays using either our Gantry or Delta Robot.

Our Gantry Robot with X, Y, Z-axis functionality is perfect for your cans, bottles, jars, cartons and similar products while our Delta Robot is the packing solution for your more flexible bags and packages.

Both robotic options provide gentle product handling by either vacuum or mechanical means, assuring product integrity and consistent tray and case packing. And we can configure either option to accommodate a wide variety of case/tray sizes and pack patterns.

These modular pick & place cells can fit into any existing production line or be integrated as part of a complete packaging solution to include automatic case erecting, tray forming, sealing and robotic palletizing.

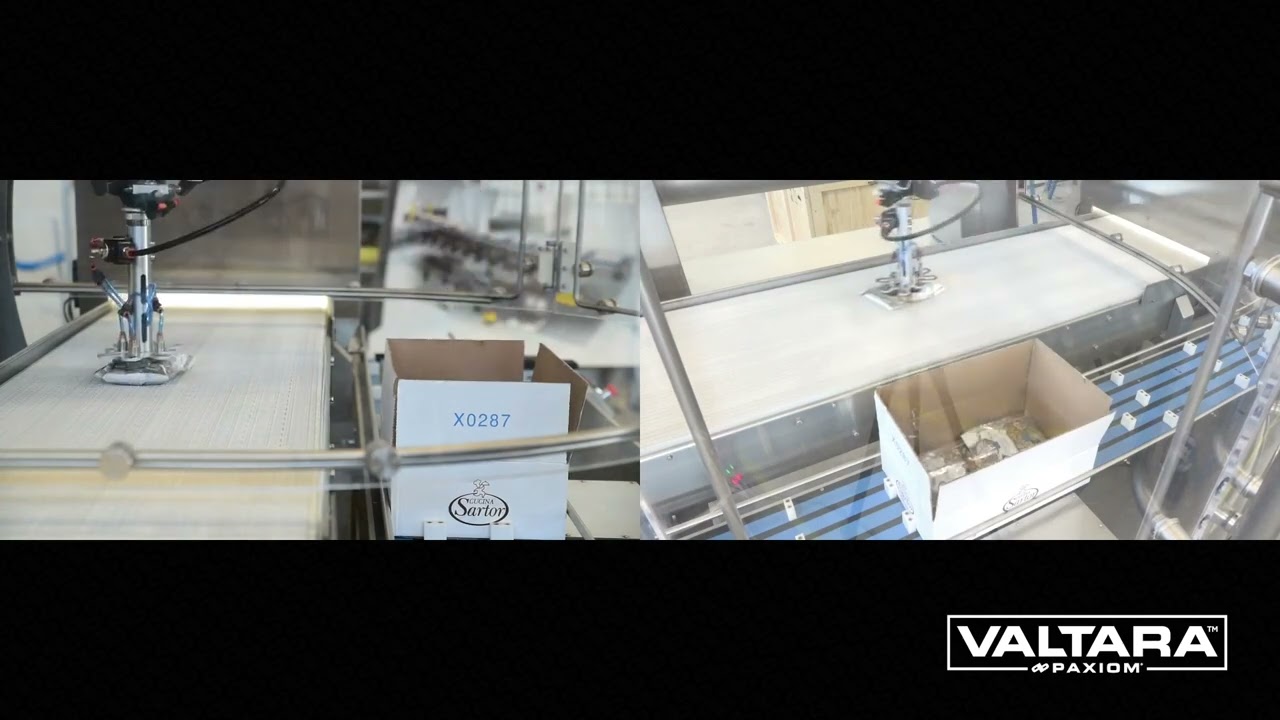

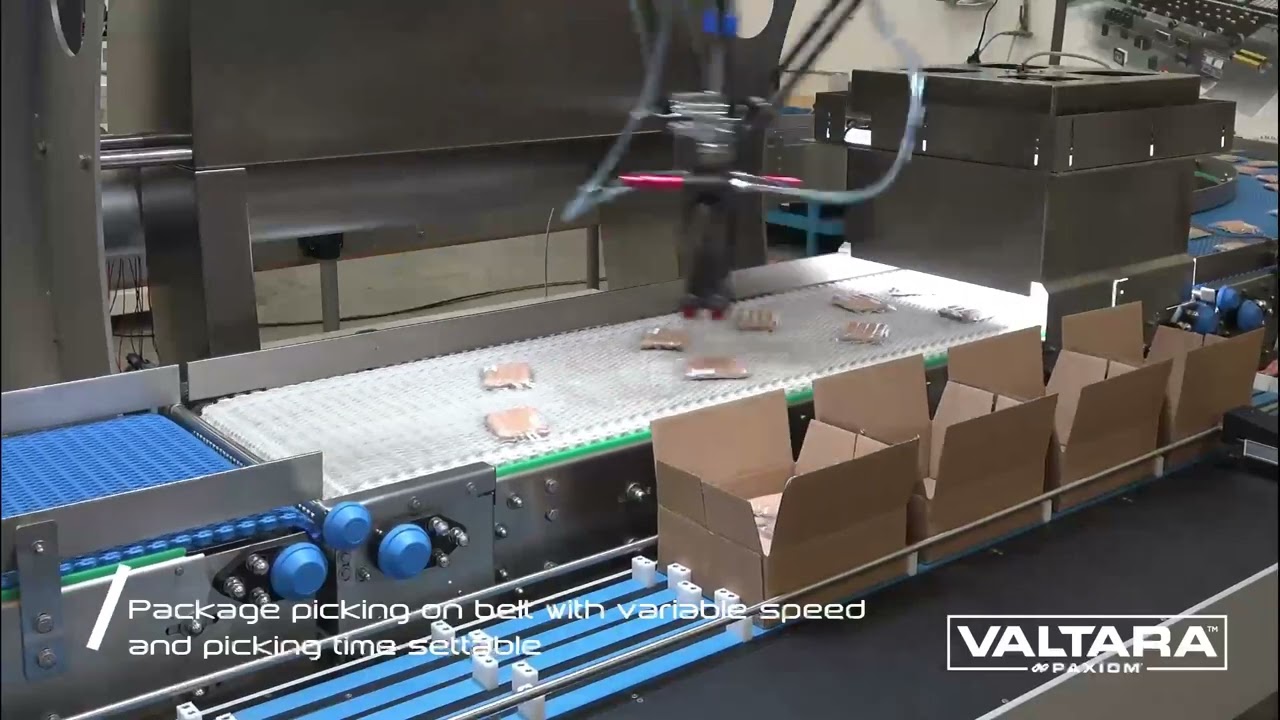

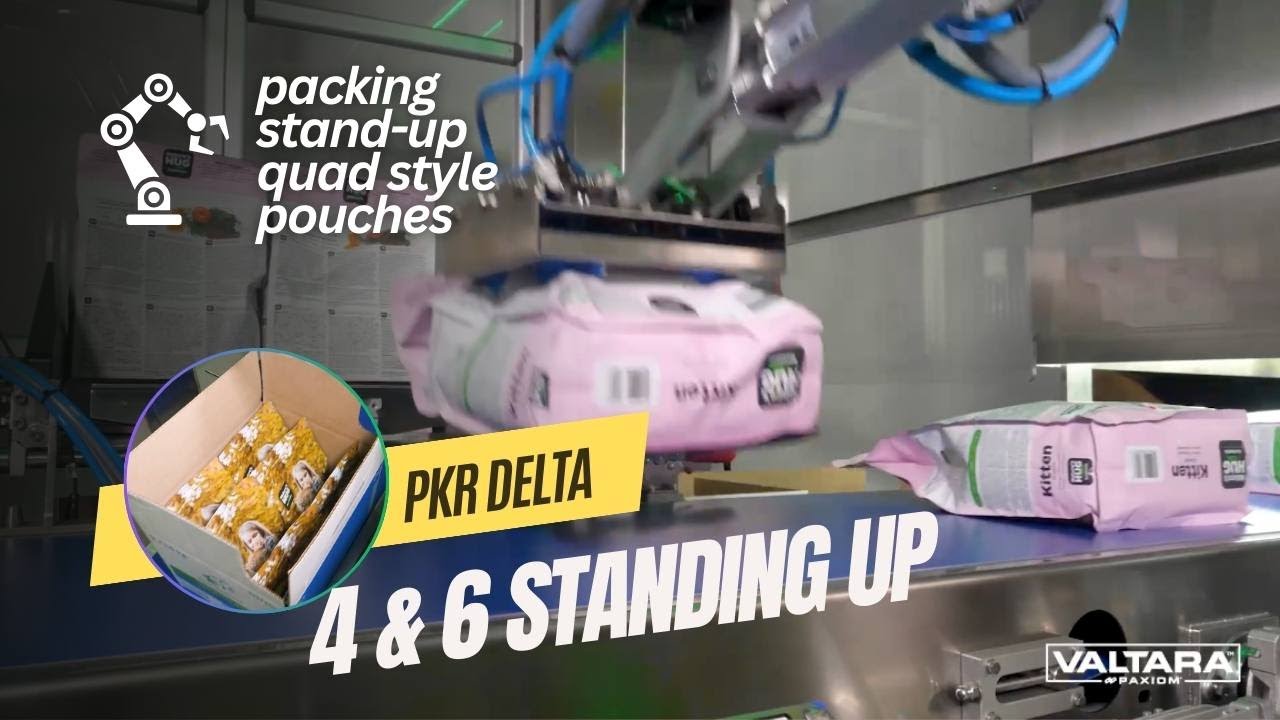

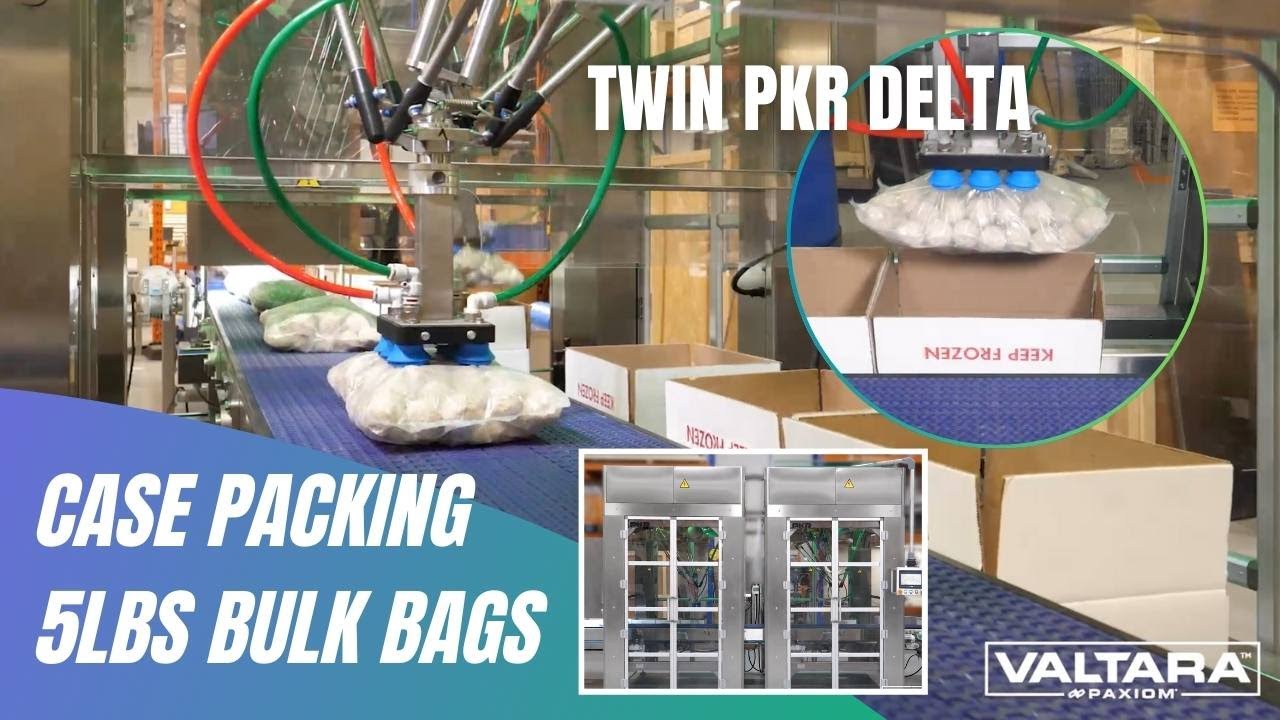

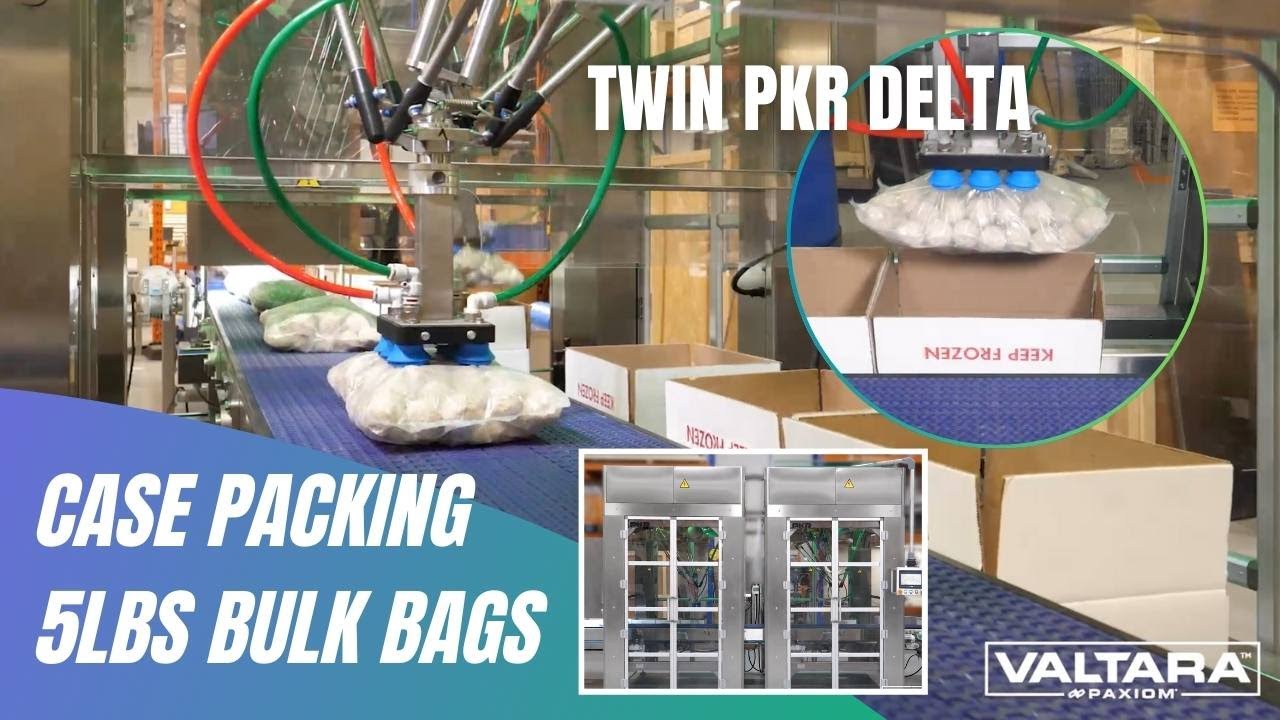

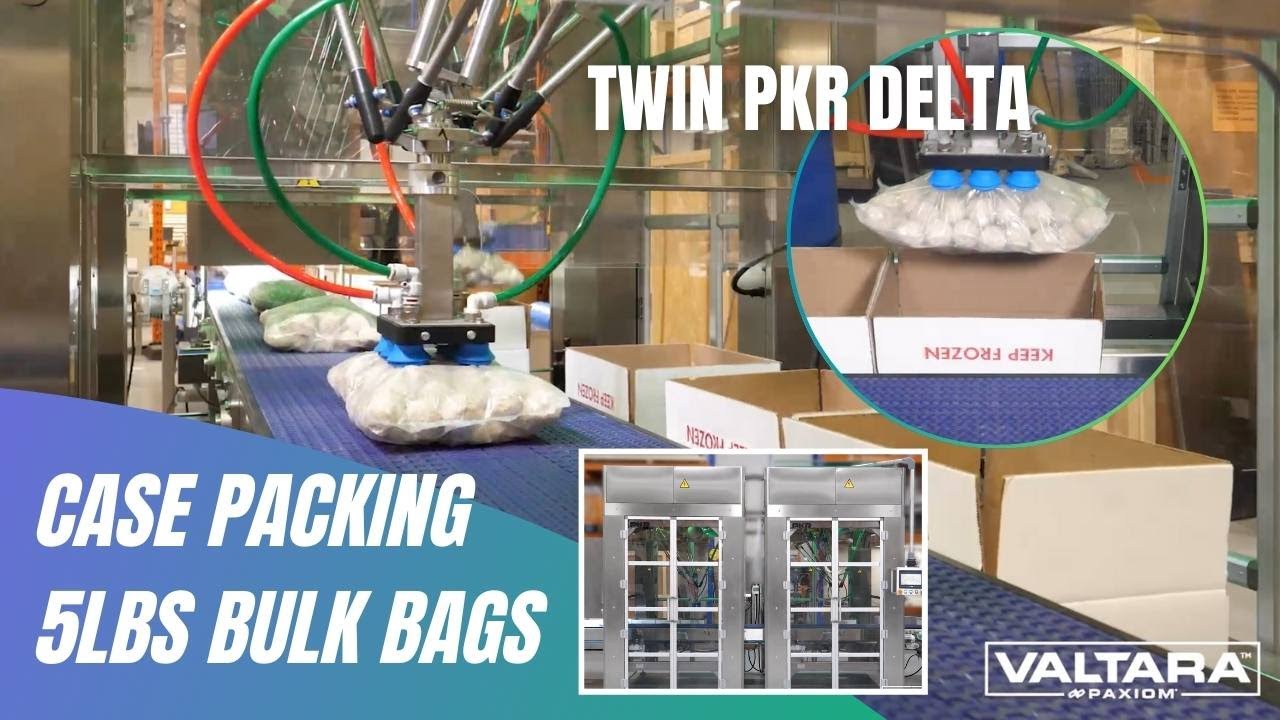

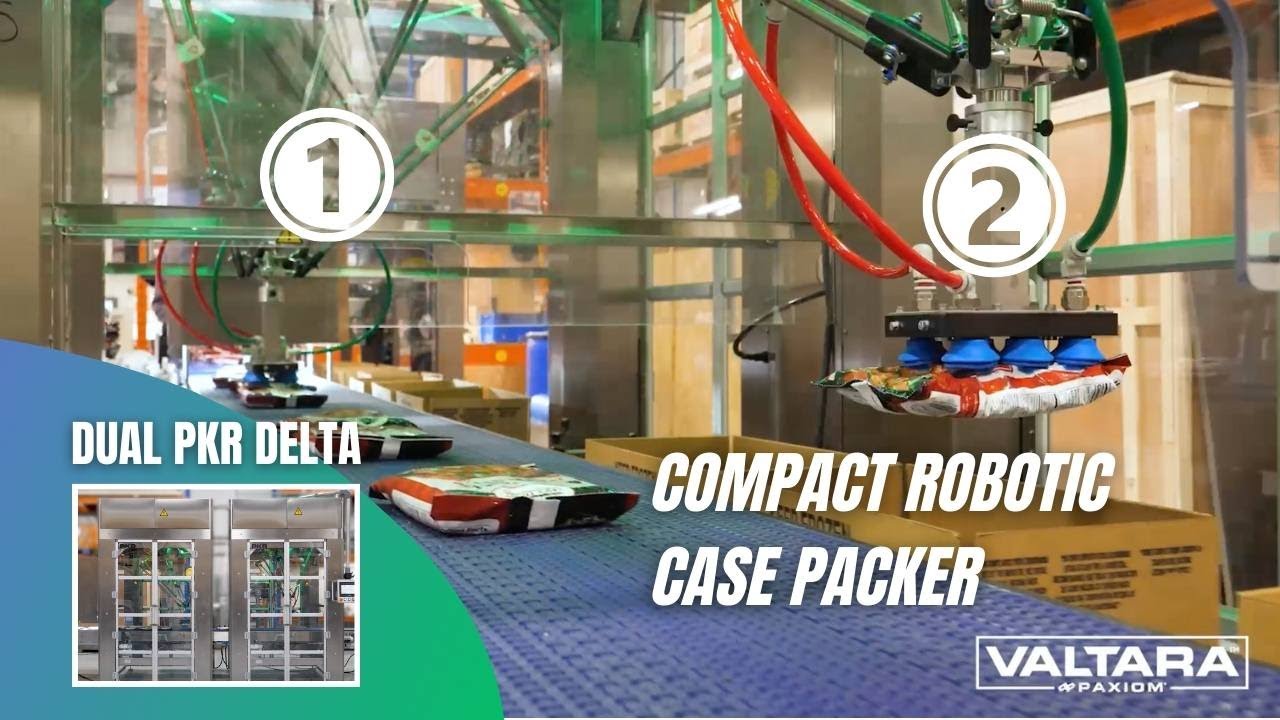

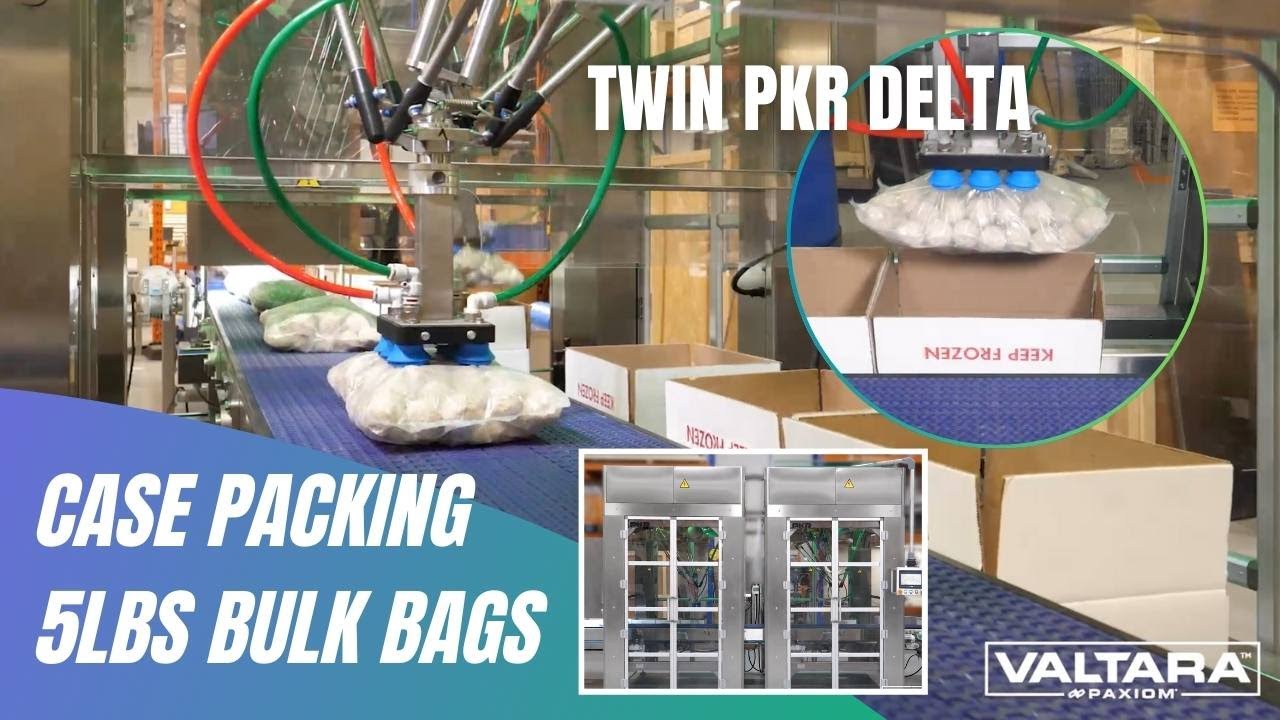

Twin PKR Delta

Robotic Pick & Place Case Packing System

Videos

Discover our Twin PKR Delta Pick and Place system that can expertly pack bags and other flexible packages into boxes or trays with unmatched efficiency. Perfect for various retail or bulk packaging applications, this advanced system utilizes high-resolution vision technology and innovative Codian Delta Robots.

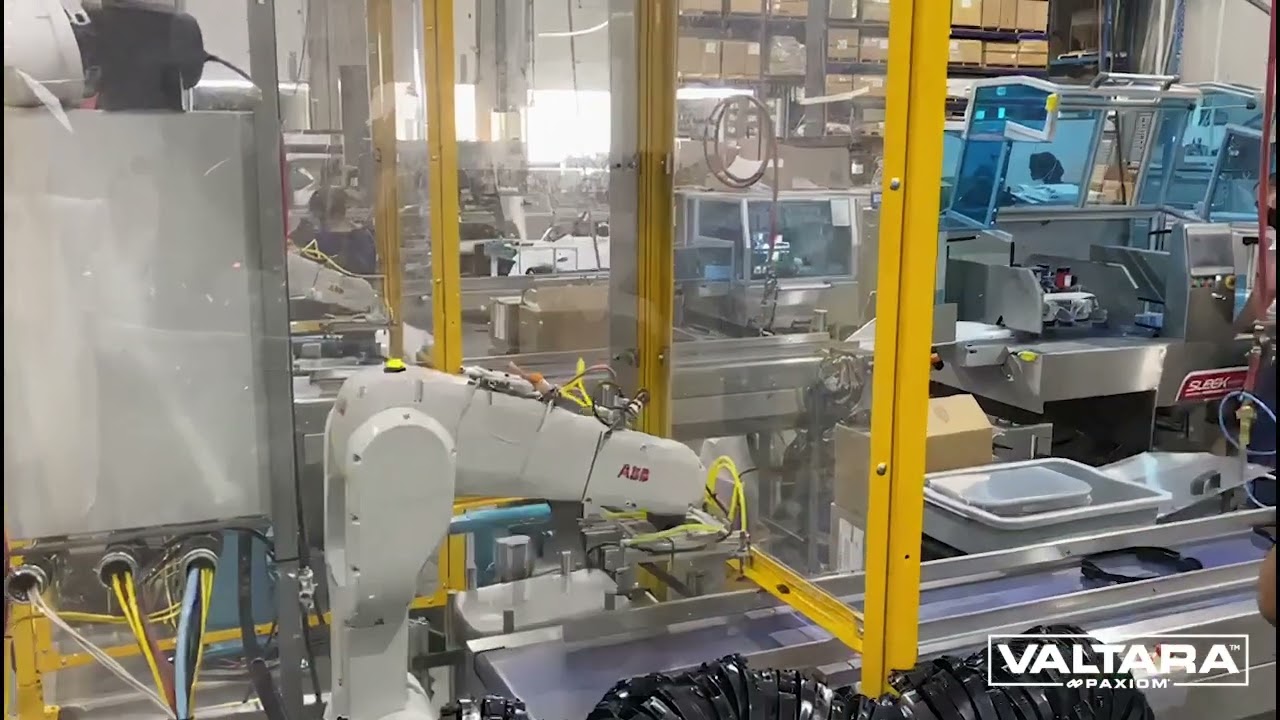

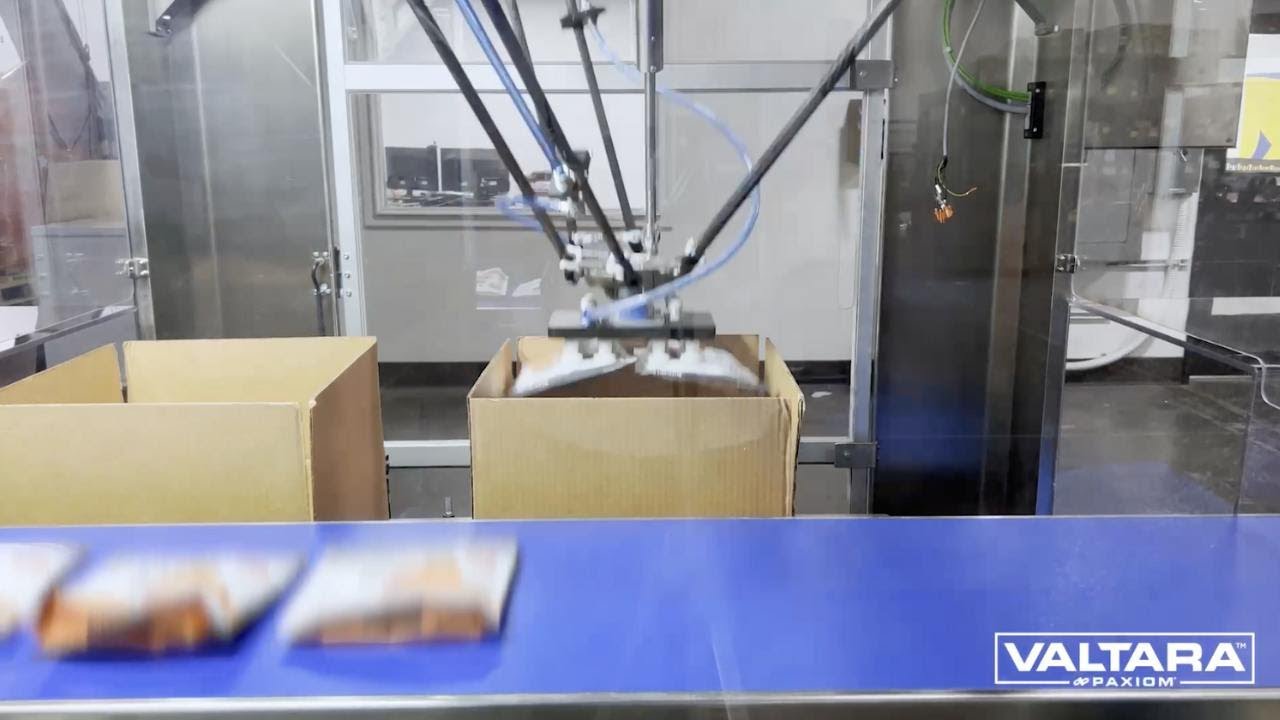

Robotic Loading

Precise product placement

Robotic Loading Systems

Videos

We can custom engineer an automatic loading system for your flow wrapping process using one of our PKR pick and place systems.

We can design your system using either our Delta, Gantry or SCARA robot platform and precisely place your product for loading onto the conveyor of one of our flow wrappers or onto your existing flow wrapping machine.

This robotic loading system eliminates the traditional repetitive motion stations, reducing overhead and risky labor practices while increasing efficiencies and throughput.

PKR Delta

Delta Spider Pick & Place Cell

Videos

Our PKR modular pick & place cells will automatically top-load your product into cases or trays using either our Gantry or Delta Robot.

Our Gantry Robot with X, Y, Z-axis functionality is perfect for your cans, bottles, jars, cartons and similar products while our Delta Robot is the packing solution for your more flexible bags and packages.

Both robotic options provide gentle product handling by either vacuum or mechanical means, assuring product integrity and consistent tray and case packing. And we can configure either option to accommodate a wide variety of case/tray sizes and pack patterns.

These modular pick & place cells can fit into any existing production line or be integrated as part of a complete packaging solution to include automatic case erecting, tray forming, sealing and robotic palletizing.

Twin PKR Delta

Robotic Pick & Place Case Packing System

Videos

Discover our Twin PKR Delta Pick and Place system that can expertly pack bags and other flexible packages into boxes or trays with unmatched efficiency. Perfect for various retail or bulk packaging applications, this advanced system utilizes high-resolution vision technology and innovative Codian Delta Robots.

Robotic Loading

Precise product placement

We can custom engineer an automatic loading system for your flow wrapping process using one of our PKR pick and place systems.

We can design your system using either our Delta, Gantry or SCARA robot platform and precisely place your product for loading onto the conveyor of one of our flow wrappers or onto your existing flow wrapping machine.

This robotic loading system eliminates the traditional repetitive motion stations, reducing overhead and risky labor practices while increasing efficiencies and throughput.

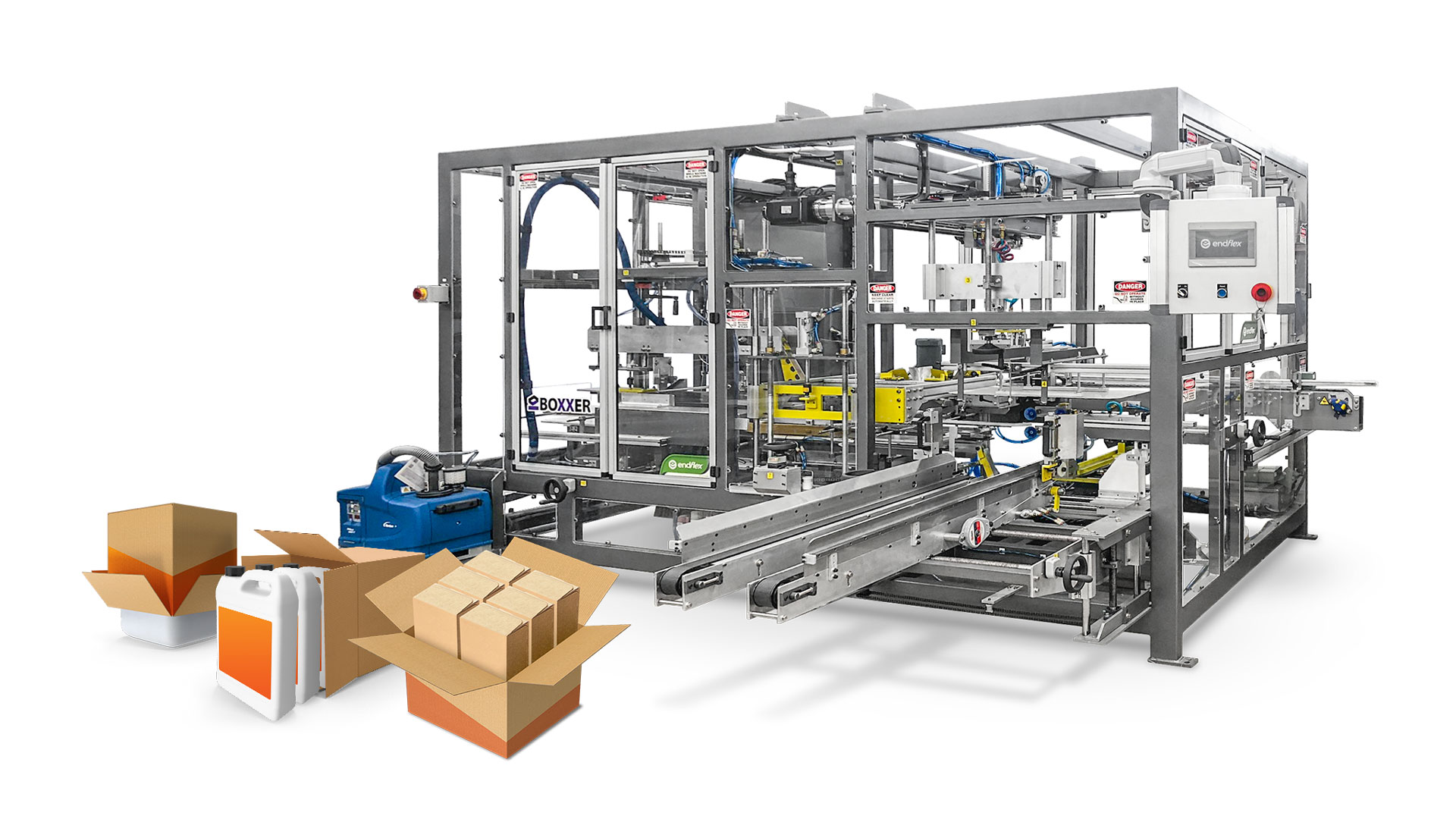

Find and customize your Case Packer

In just a few steps