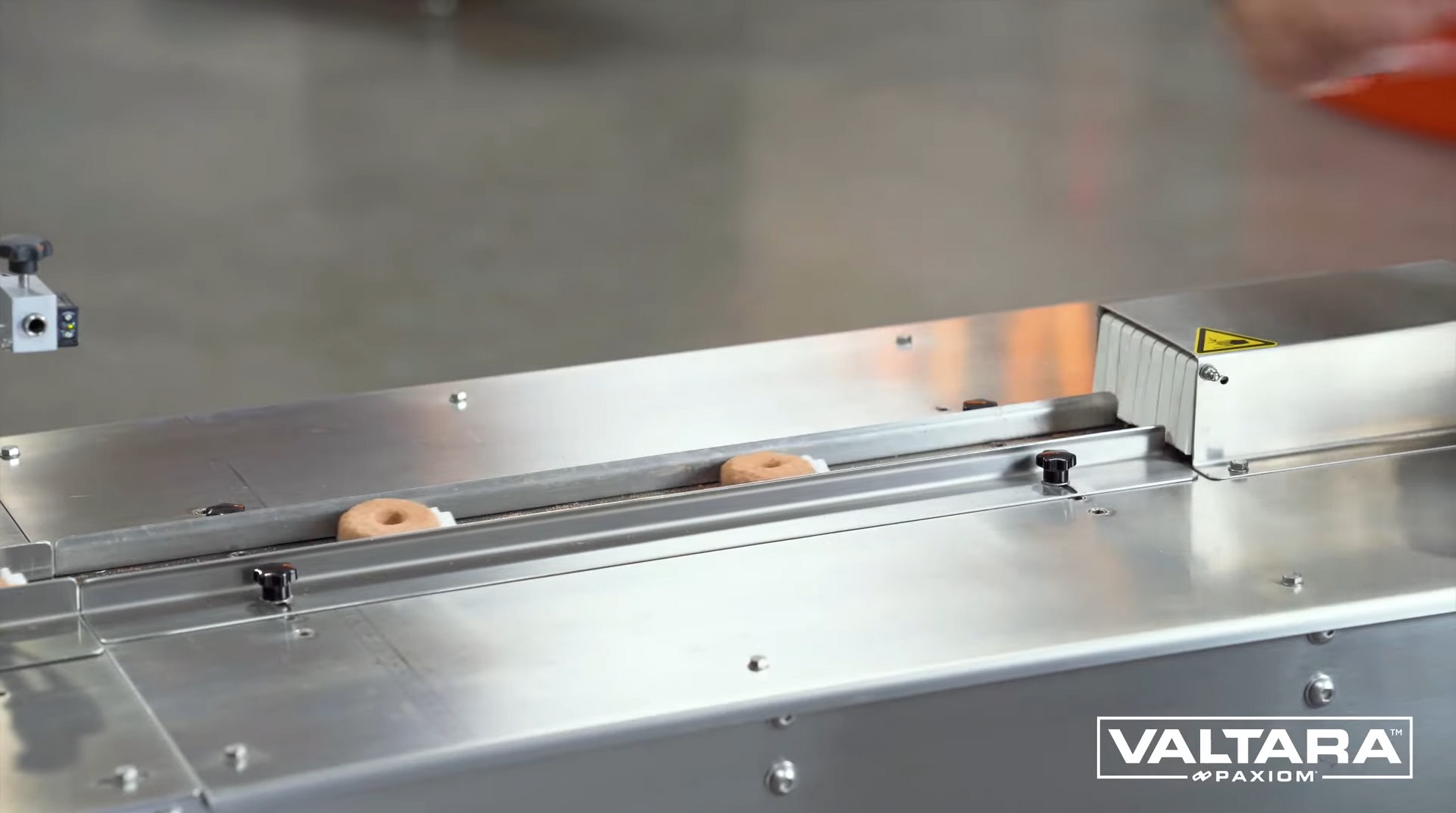

SleekWrapper F40

The Most Compact

Flow Wrapper Machine

Videos

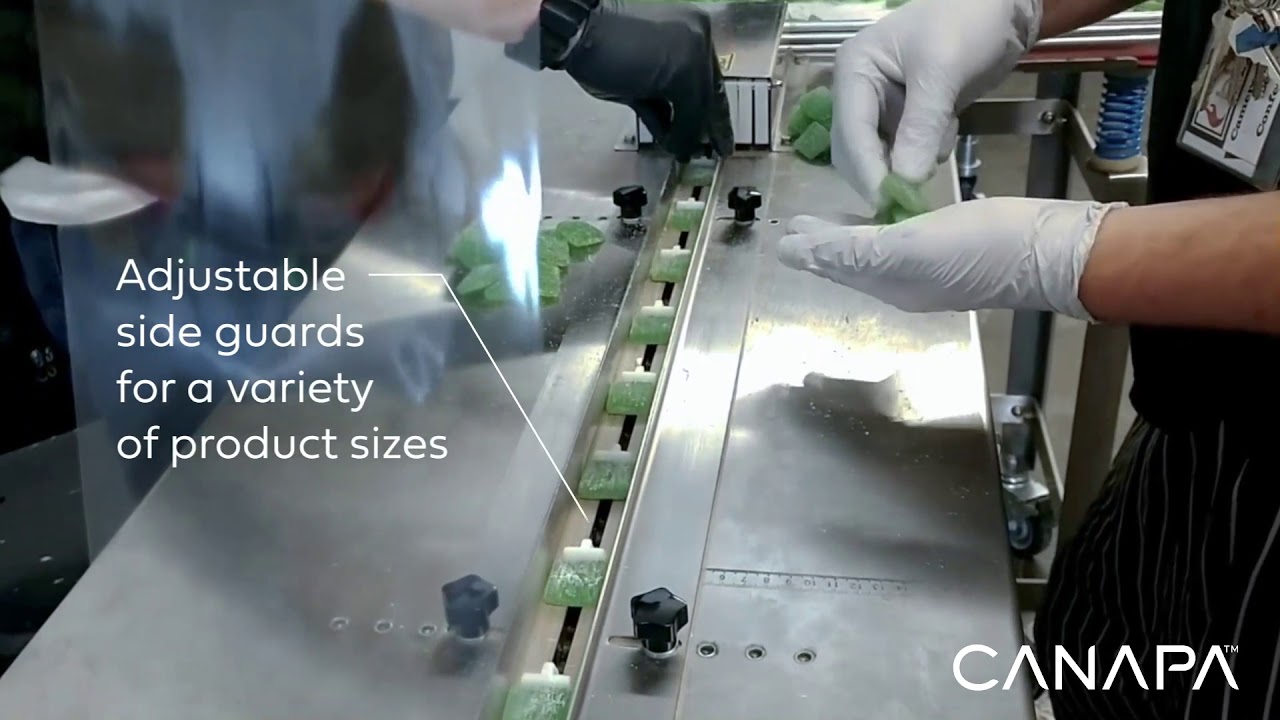

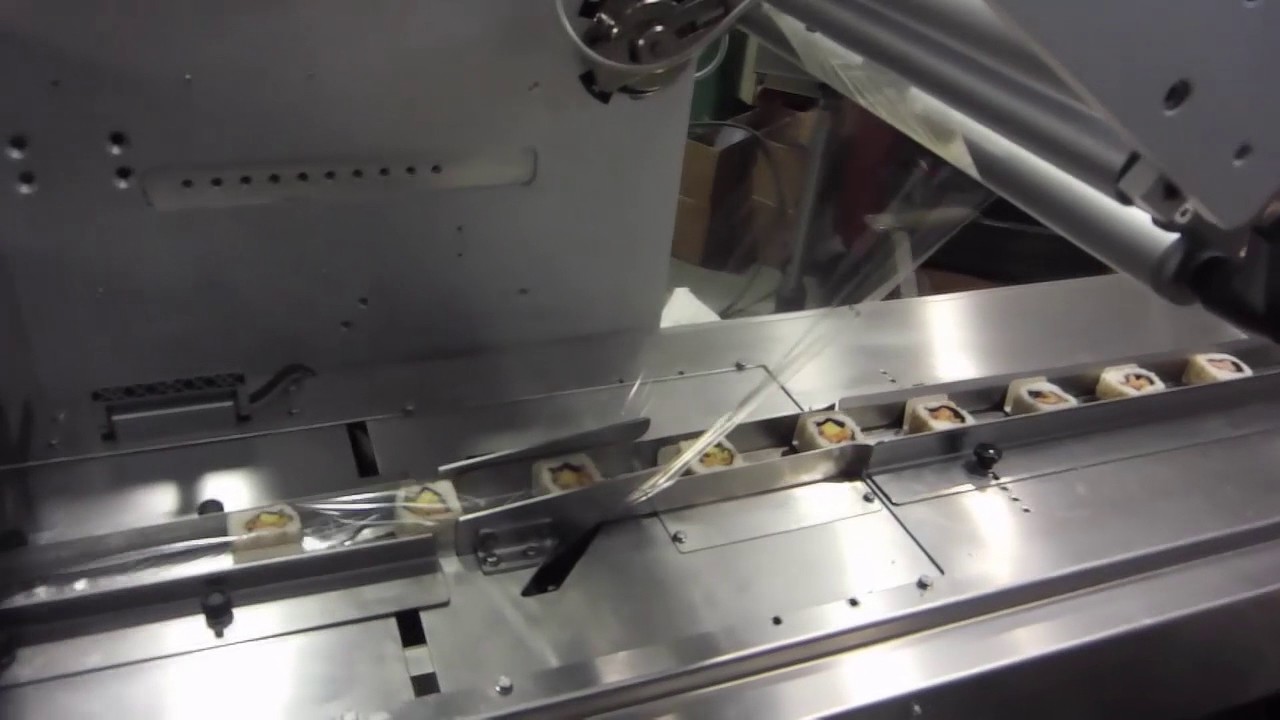

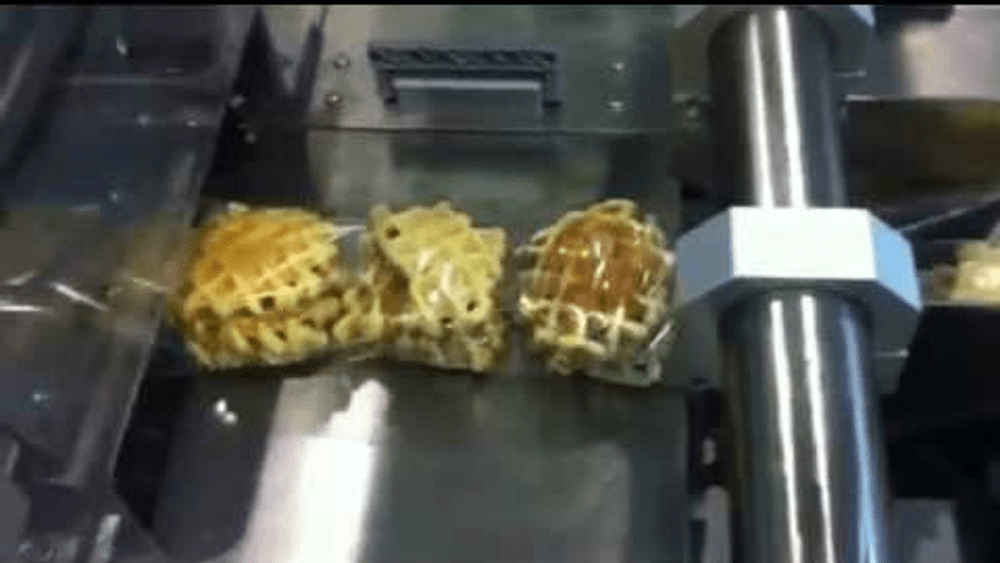

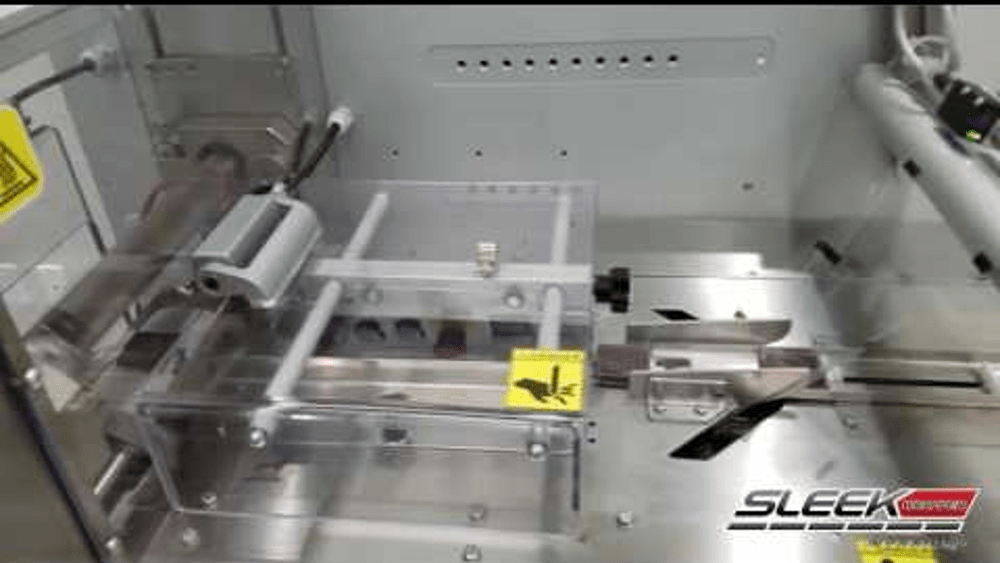

The Sleek F40 flow wrapper is designed with reliability, simplicity and serviceability in mind. Products can be quickly changed over and the machine is easily adjusted, minimizing product and film waste and reducing maintenance costs. Four servo-driven motors assure precise positioning with smooth acceleration and deceleration.

Features stainless steel frame construction, user-friendly color touchscreen, automatic open/close rotary fin wheel assembly, rotary seal jaws with jam detecting logic with the ability to preprogram and store product settings.

| Max Bag Length | Max Bag Width | Max Bag Height |

|---|---|---|

| 17.8 in (450 mm) | 7 in (175 mm) | 4.7 in (120 mm) |

| Film Web Width | Max Rate | |

| 15.5 in (400 mm) | 1-up jaw: 60 per min 2-up jaw: 120 per min |

*Rates subject to package style, type and size

SleekWrapper 40

For high speed flow wrapping

Videos

Image Gallery

The Sleek F40 flow wrapper is designed with reliability, simplicity and serviceability in mind. Products can be quickly changed over and the machine is easily adjusted, minimizing product and film waste and reducing maintenance costs. Four servo-driven motors assure precise positioning with smooth acceleration and deceleration.

Features stainless steel frame construction, user-friendly color touchscreen, automatic open/close rotary fin wheel assembly, rotary seal jaws with jam detecting logic with the ability to preprogram and store product settings.

| Max Bag Length | Max Bag Width | Max Bag Height |

|---|---|---|

| 17.8 in (450 mm) | 7 in (175 mm) | 4.7 in (120 mm) |

| Film Web Width | Max Rate | |

| 15.5 in (400 mm) | 1-up jaw: 60 per min 2-up jaw: 120 per min |

*Rates subject to package style, type and size