SleekWrapper i65

Inverted Flow Wrapper

Videos

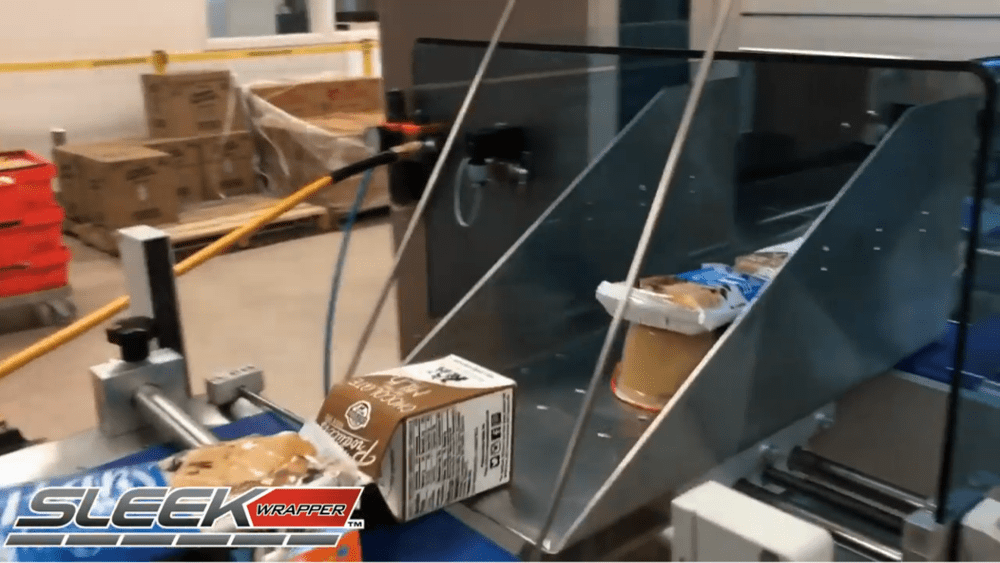

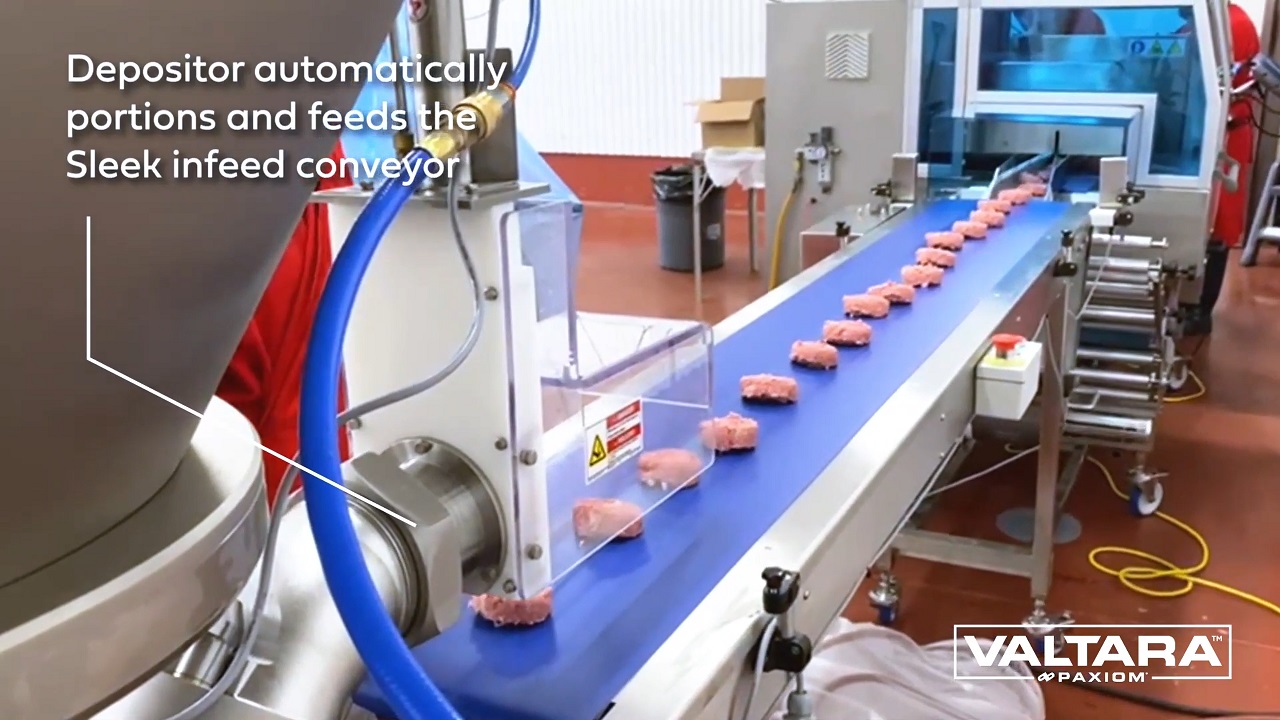

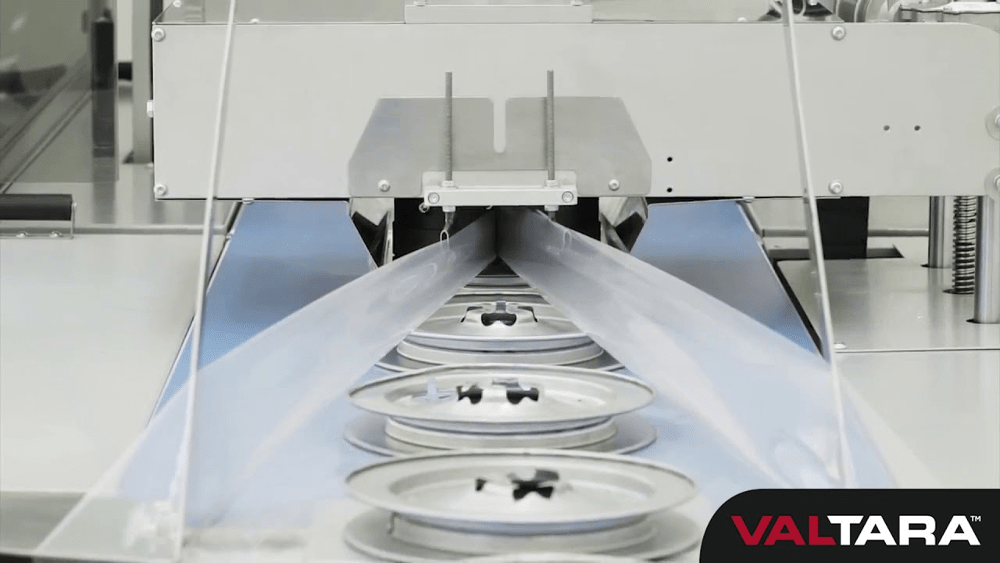

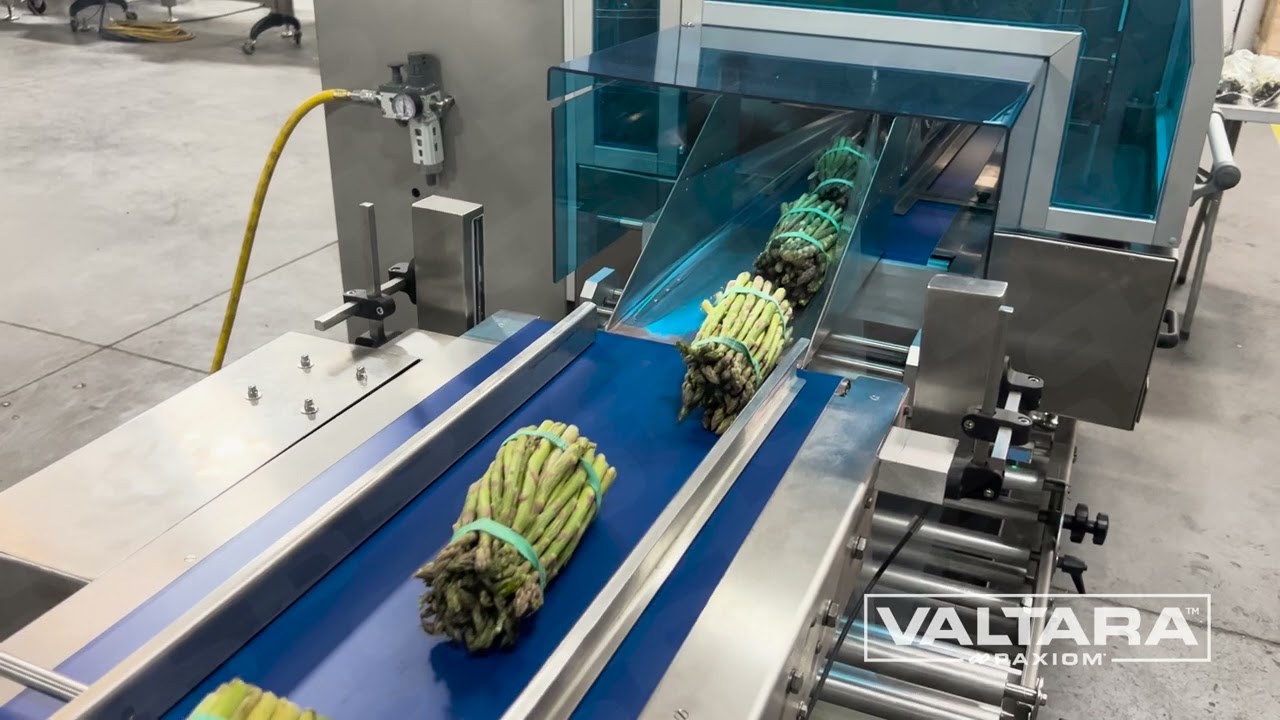

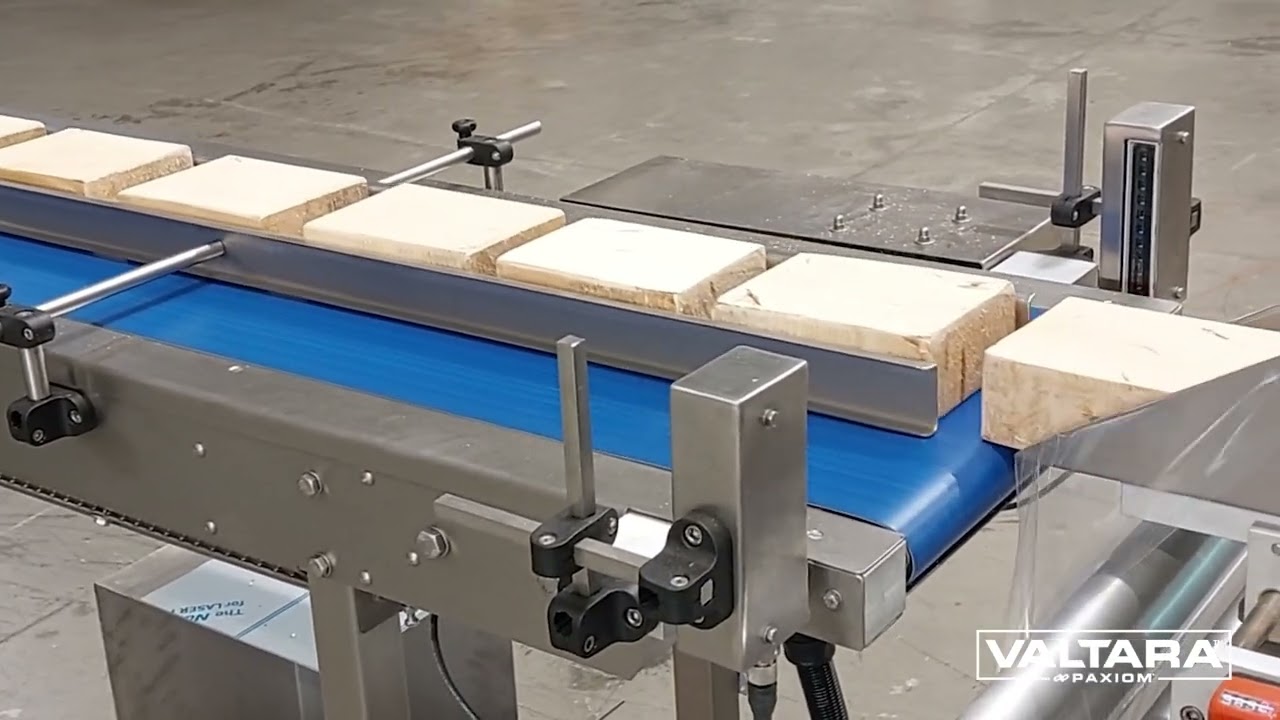

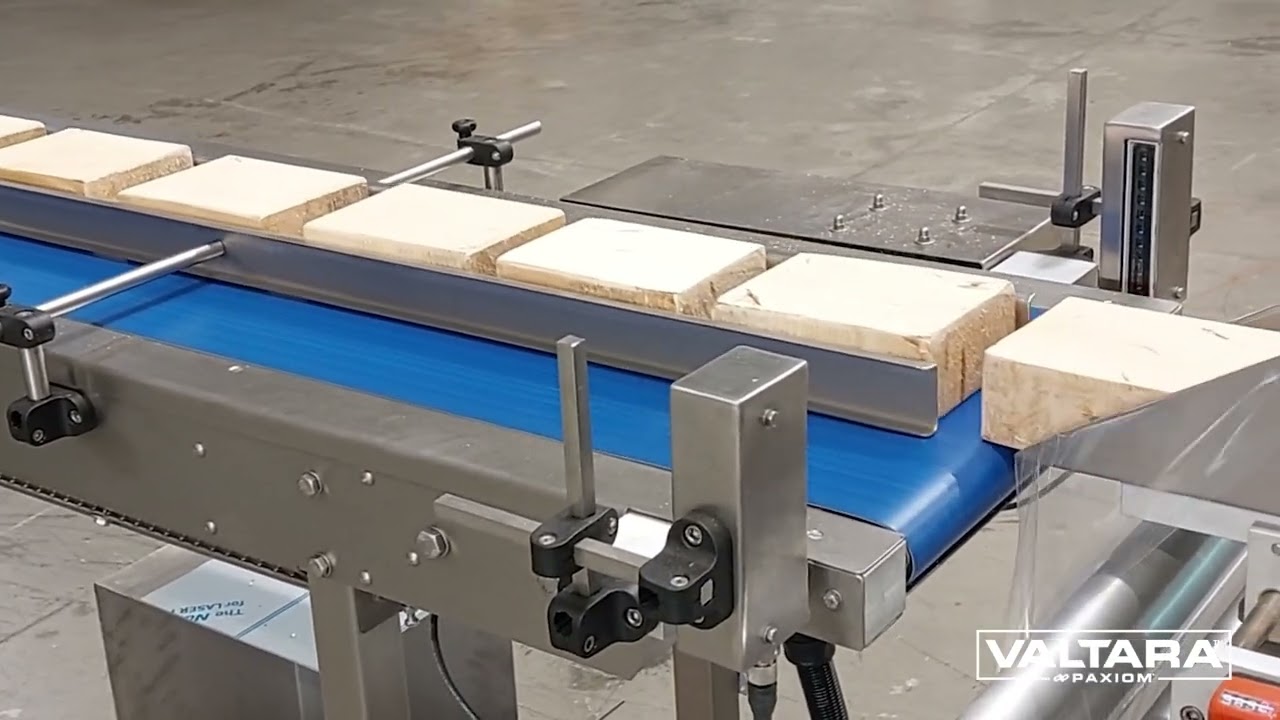

The SleekWrapper i65 flow wrapper is ideal for fresh, soft or sticky products, multipacks and other products that need to be carried instead of pushed, as typically happens with the chain design found on conventional bottom seal flow wrappers. Our inverted wrapper feeds the film from below so your hard-to-handle products are securely carried on top of the packaging film from the former through to the cutting head. Five servo-driven motors assure precise positioning with smooth acceleration and deceleration.

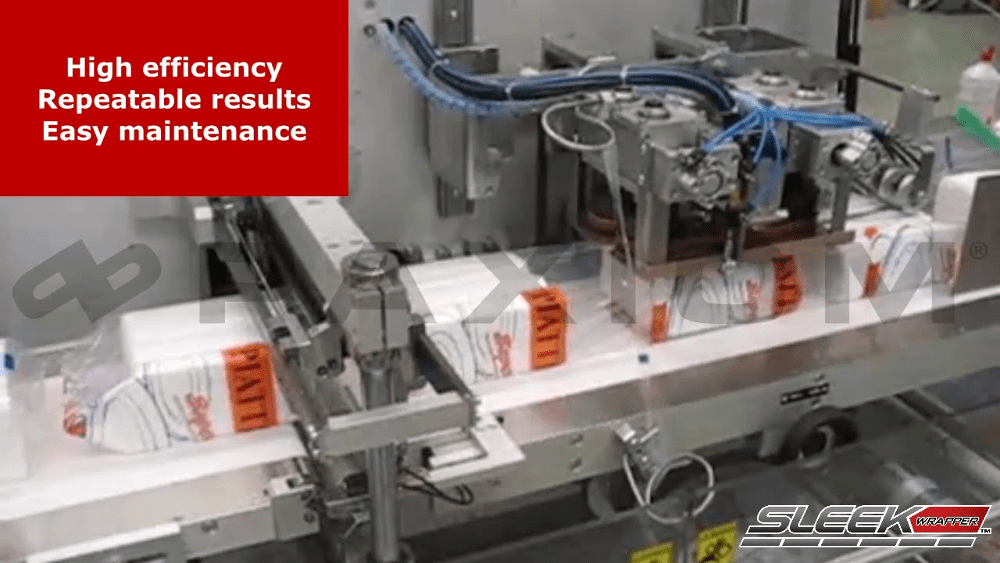

Designed with serviceability in mind and built for a 24/7 environment, the i65 features stainless steel frame construction, user-friendly color touchscreen, automatic open/close rotary fin wheel assembly, rotary seal jaws with jam detecting logic with the ability to preprogram and store product settings.

| Max Bag Length | Max Bag Width | Max Bag Height |

|---|---|---|

| 24 in (620 mm) | 11 in (280 mm) | 5.5 in (139 mm) |

| Film Web Width | Max Rate | |

| 25.5 in (650 mm) | Box motion: 60 per min Intermittent: 30 per min |

*Rates subject to package style, type and size

SleekWrapper i65

Inverted

Videos

The SleekWrapper i65 flow wrapper is ideal for fresh, soft or sticky products, multipacks and other products that need to be carried instead of pushed, as typically happens with the chain design found on conventional bottom seal flow wrappers. Our inverted wrapper feeds the film from below so your hard-to-handle products are securely carried on top of the packaging film from the former through to the cutting head. Five servo-driven motors assure precise positioning with smooth acceleration and deceleration.

Designed with serviceability in mind and built for a 24/7 environment, the i65 features stainless steel frame construction, user-friendly color touchscreen, automatic open/close rotary fin wheel assembly, rotary seal jaws with jam detecting logic with the ability to preprogram and store product settings.

| Max Bag Length | Max Bag Width | Max Bag Height |

|---|---|---|

| 24 in (620 mm) | 11 in (280 mm) | 5.5 in (139 mm) |

| Film Web Width | Max Rate | |

| 25.5 in (650 mm) | Box motion: 60 per min Intermittent: 30 per min |

*Rates subject to package style, type and size